How to design a crate mould

Designing a crate mold involves several steps to ensure the mold meets the requirements for producing durable and functional crates. Here’s a general outline of the process:

1. Define Requirements and Specifications

- Purpose: Understand the purpose of the crate (e.g., transportation, storage).

- Dimensions: Determine the size and shape of the crate.

- Material: Select the appropriate material (e.g., plastic, metal) based on durability and cost considerations.

- Quantity: Estimate the production volume to determine the type of mold (e.g., prototype mold, production mold).

2. Conceptual Design

- Sketch Design: Create initial sketches or use CAD software to develop a basic design of the crate.

- Considerations: Ensure the design includes features such as handles, stacking capability, and any required labels or markings.

3. Detailed Design

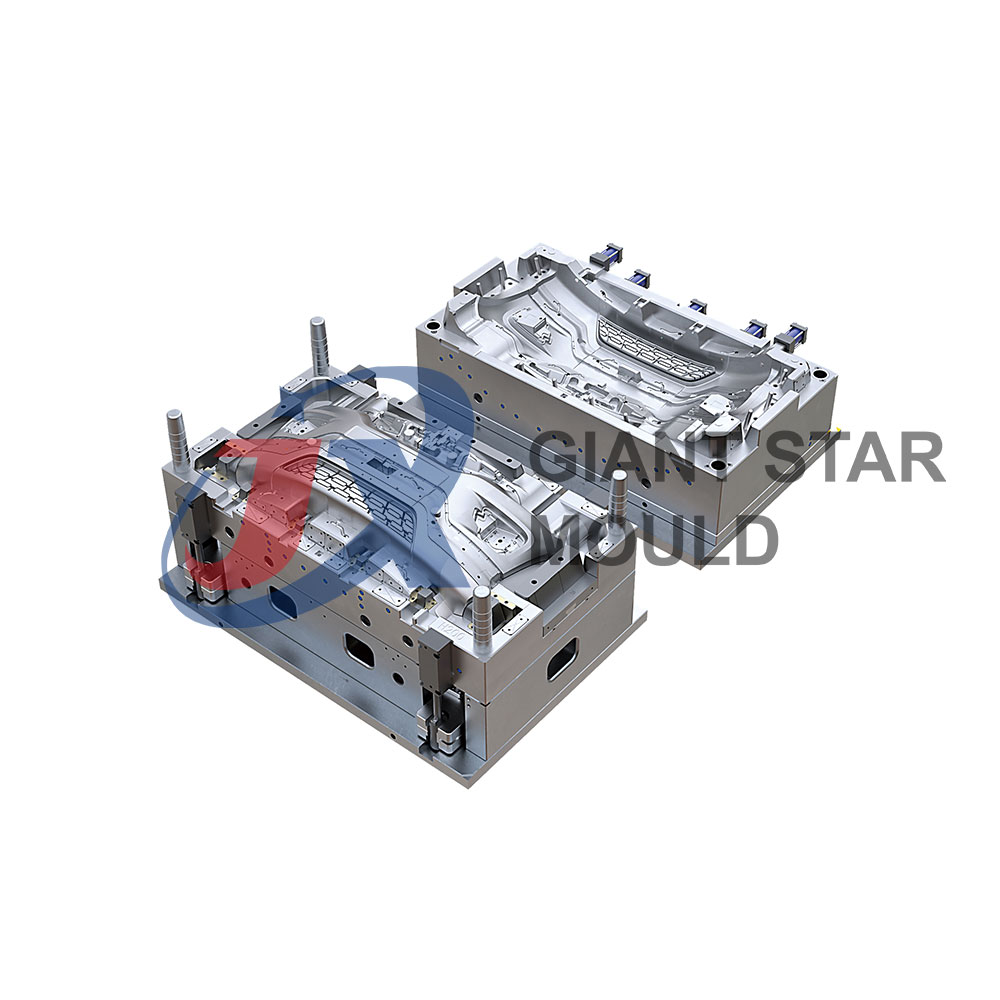

- CAD Modeling: Use computer-aided design (CAD) software to create a detailed 3D model of the crate.

- Wall Thickness: Determine appropriate wall thickness for structural integrity and material usage efficiency.

- Draft Angles: Incorporate draft angles to facilitate easy mold release.

- Gate and Runner System: Design the gate (where the molten material enters the mold) and runner system (channels that distribute material to multiple cavities).

4. Mold Flow Analysis

- Simulation: Conduct mold flow analysis using specialized software to predict material flow, cooling times, and potential issues (e.g., air traps, weld lines).

- Optimization: Modify the design based on simulation results to ensure uniform filling and optimal part quality.

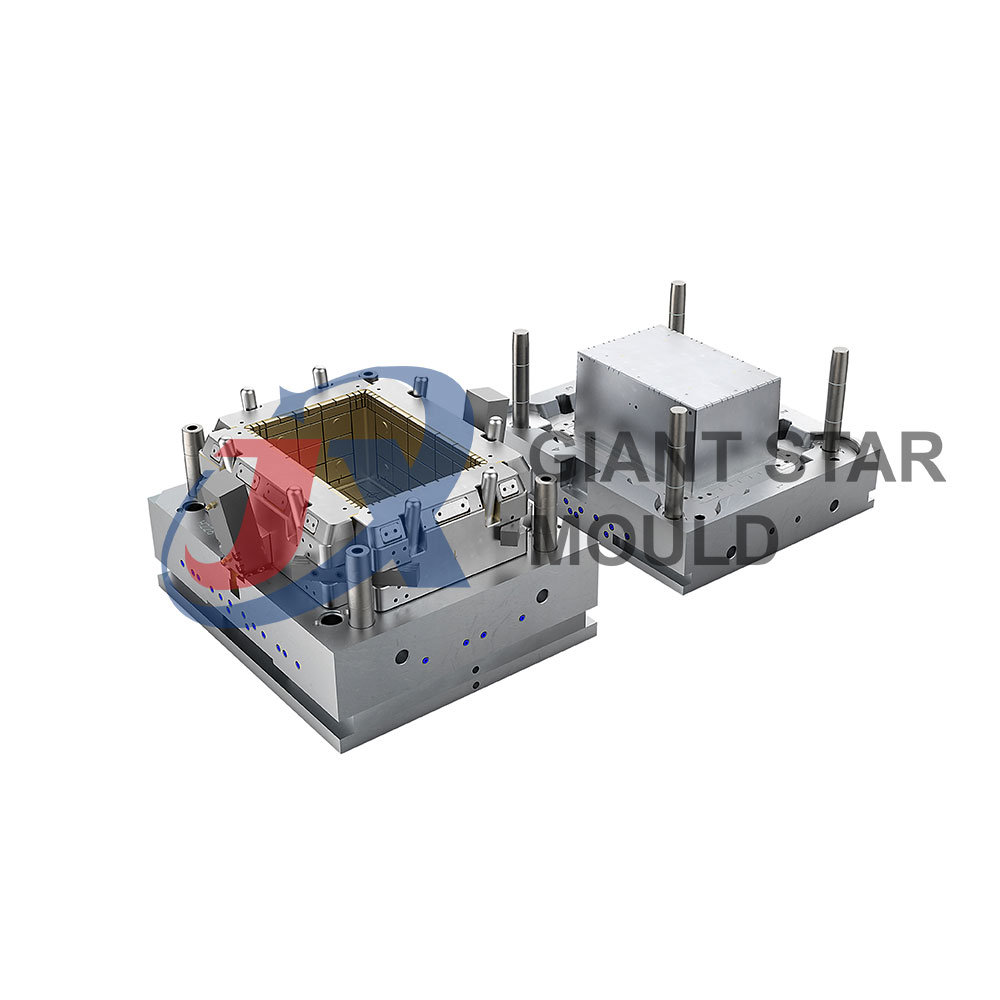

5. Tooling Design

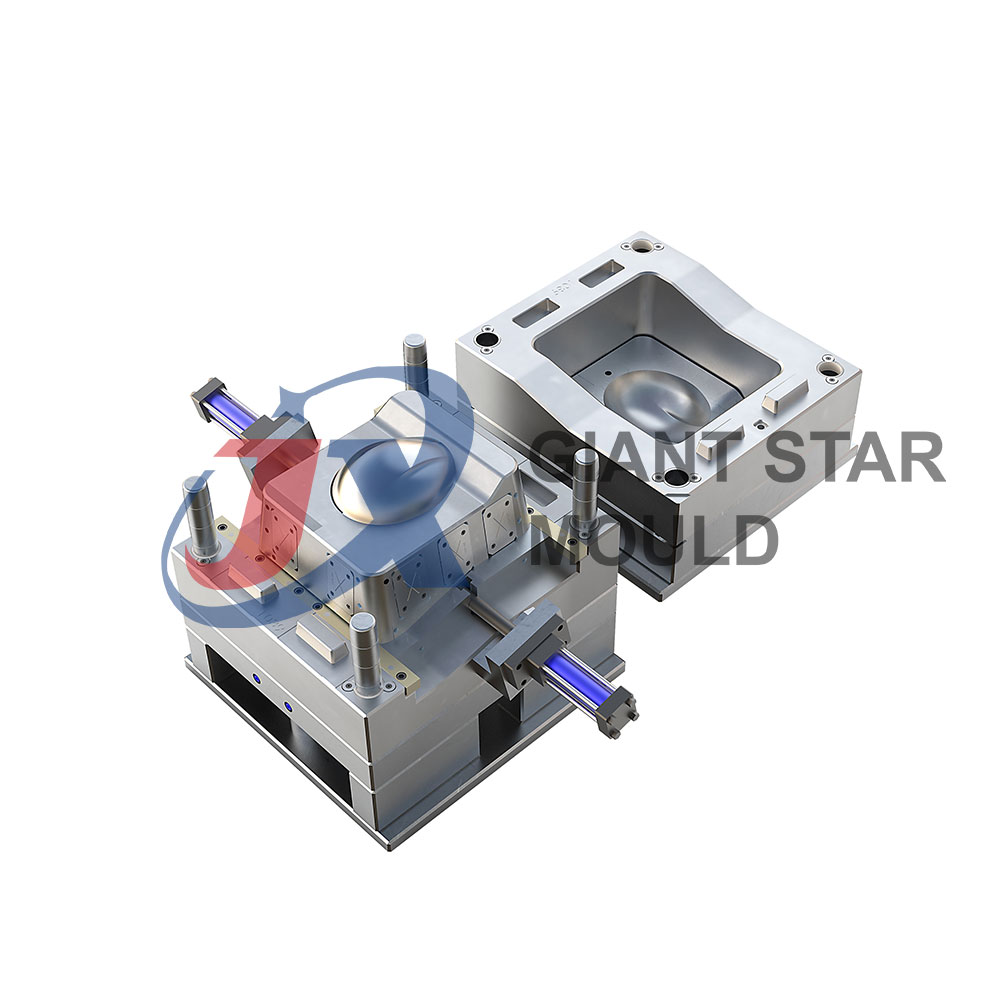

- Core and Cavity: Design the core and cavity of the mold to form the shape of the crate.

- Cooling System: Include a cooling system to regulate mold temperature and ensure proper material solidification.

- Ejection System: Integrate an ejection system (e.g., ejector pins) to remove the crate from the mold after cooling.

6. Manufacturing the Mold

- Machining: Use CNC machining or other manufacturing processes to create the mold components with precision.

- Surface Finish: Apply appropriate surface finishes to the mold to achieve the desired texture on the crate surface.

7. Testing and Validation

- Trial Runs: Conduct trial production runs to test mold functionality and crate quality.

- Adjustments: Make adjustments as necessary based on trial results to optimize part quality and mold performance.

8. Production

- Full Production: Once the mold design is validated, start full-scale production of crates using the finalized mold.

Additional Considerations:

- Maintenance: Plan for regular maintenance of the mold to prolong its lifespan and ensure consistent quality.

- Documentation: Maintain detailed documentation of the mold design and production process for future reference and replication.

Designing a crate mold involves expertise in mold design, materials science, and manufacturing processes. Collaboration with mold makers, engineers, and material suppliers is often necessary to achieve an efficient and cost-effective mold design.